Futuristic technology is already here, it’s called 3D printing

Science

1. What can’t you 3D print?

deTeched

Science fiction fantasies are coming alive with 3D printing, which seems to create a fully functioning object out of nothing. Of course, it’s actually more science-y than that. 3D printers are in hospitals, in space, and even in restaurants. Will our future be manufactured by 3D printers? Most likely. But that future is already here, because 3D printers are currently making just about anything, from food to organs to electronics. It’s amazing what they can do now and it almost seems like nothing can’t be 3D printed. Welcome to the future.

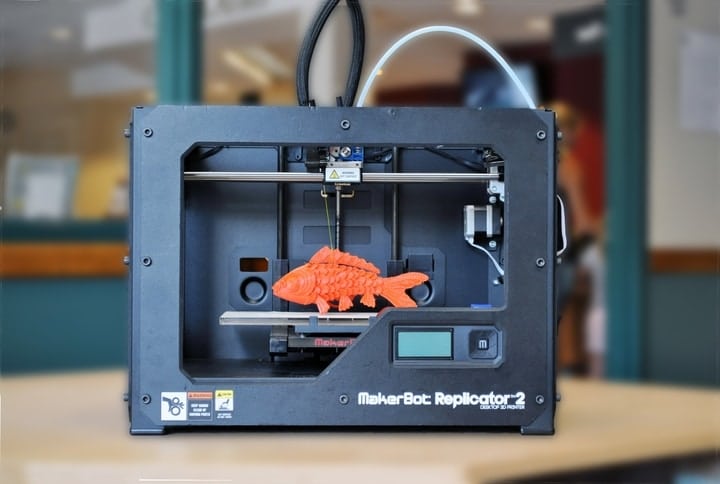

3D printing is an incredible reminder that we really are living in the future. It’s only been popular in the public for the last decade or so. But surprisingly, 3D printing was actually invented in the 1980’s. Until recently, however, its image has mostly been centered around only somewhat useful hard plastic items.

Computerworld

These plastic things certainly have some uses, like as toys or prototypes, but the material can’t be used for everything. Fortunately, colorful plastic isn’t the only material 3D printers are using. There are actually a lot more types, and they’ll definitely surprise you. In the future, we’ll probably see almost everything 3D printed.

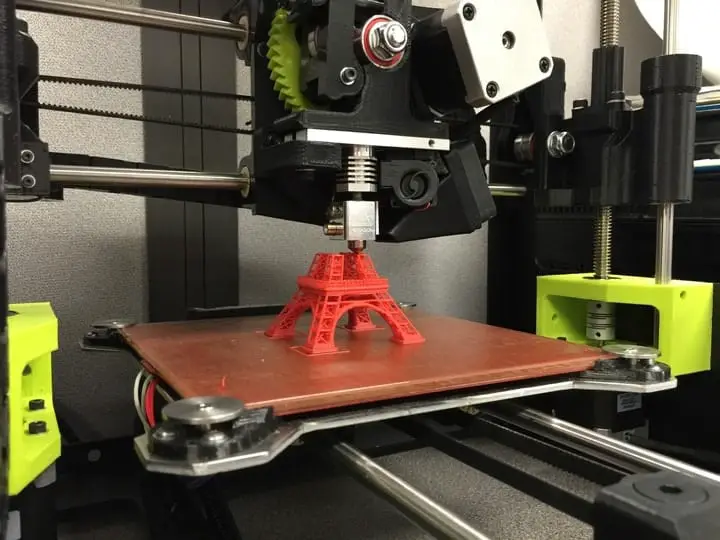

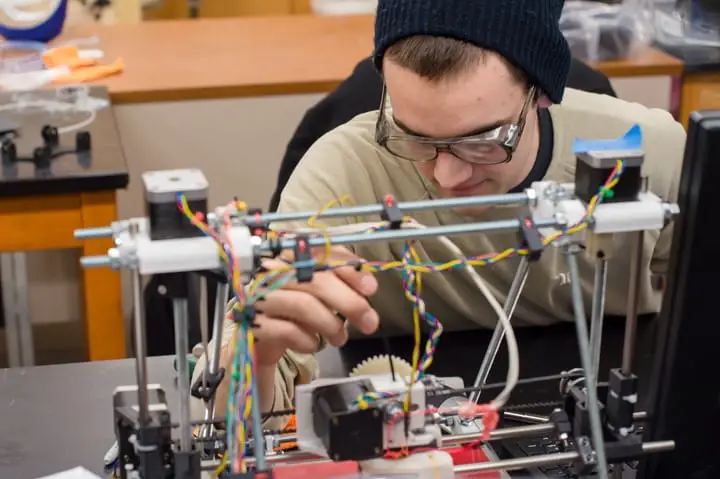

2. Inky varieties

To print, a 3D printer must first read a digital 3D file, aka the blueprint, and then layer materials on top of each other, to make a three dimensional creation. These materials are like the ink of your normal printer, but 3D printers have a lot more variation in the types of “inks” they use.

DIY 3D Printing

Nowadays, 3D printers can use everything from cement to living cells to pizza dough as their ink. And while 3D printing is not finding its home in your home, since it hasn’t taken off for regular consumers, it has great potential in a variety of industries. But what’s the point of using 3D printing at all?

3. Why 3D print?

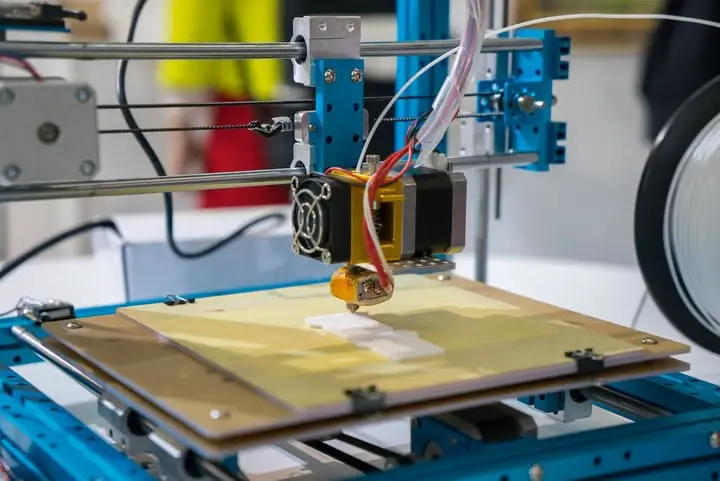

Is 3D printing really more than just a gimmick? Yup, 3D printing, or “additive manufacturing,” offers several advantages over standard manufacturing methods. For one, it’s great for making prototypes of products because it’s pretty cheap and fast. 3D printers may have a reputation for being expensive, but they can be the cheaper choice.

Sastra Robotics

Generally, 3D printing is good for things that aren’t mass produced because it doesn’t cost as much to make a single item. Because of this, 3D printing excels at making customized stuff. With the aid of 3D digital scanning, a file can be tweaked as needed to be a perfect fit. So what are these advantages being used for? Some really cool stuff, that’s what.

4. Printing homes

Earlier this year, a 650 square foot house was 3D printed in less than 24 hours. The total cost was about $10,000 and it had everything you would need: living room, kitchen, bedroom, bathroom, and a porch. It was the first 3D printed house in the US; a larger one was printed in France.

The Verge

The house was printed with concrete, layer by layer. 3D printing made the building go faster, for cheaper. New Story, the company behind the project, plans to make a whole community of these houses in El Salvador, with houses costing just $4,000. They’re hoping to make these houses in a lot of developing countries.

5. New shapes and sizes

This year also saw the very first family to move into a 3D printed house. Built in France, the house is 1022 square feet with four bedrooms. So, 3D printing can make bigger houses than the small one in the US. Plus, printing reduces building waste to pretty much zero.

Pop-Up City

Using 3D printing, the architects were able to design the house to curve around 100-year-old trees on the land. The shape would have been hard to build in the typical way. While this house was obviously more expensive than the one bedroom in the US, it was cheaper to make with 3D printing than if it had been built traditionally.

6. On the streets

Okay so imagine you live in a 3D printed house, but what are you going to drive? A 3D printed car, obviously. Many types of cars have been printed, but the cars have varying amounts of 3D printed parts, from just a few pieces to almost the whole car. Most have at least a 3D printed body.

BMW Group Classic EN

Some old cars, like Elvis’s BMW 507, have been restored using 3D printed parts. The car had been found in someone’s barn and needed a lot of work. Since many car parts simply aren’t made anymore, 3D printing can come in handy because it easily makes them without the high manufacturing costs.

7. Little electric cars

In China, manufacturers are ramping up car production. The company X Electrical Vehicle hopes its 3D printed cars will be on the streets in 2019. The car, called LSEV, is a two-seater and would only cost about $9,500. The only parts of the car that aren’t 3D printed are the windows, tires, and chassis (the bottom framework).

Mashable avec France 24

LSEVs are electric but can only go up to about 43 miles per hour, which is not great for highways. While not ideal for an average person, they have their niche uses. For instance, postal service providers have already ordered some. If all goes well, this will be the first mass-produced 3D printed car.

8. Olli the bus

Not only is 3D printing being used to make cars, but it’s been utilized for another type of transportation. 3D printing is combining with other futuristic technologies, like IBM Watson, which is an artificial intelligence that can hold natural question-answer based conversations. It’s been added to a 3D printed self-driving bus.

MarketWatch

The bus is named Olli and it’s currently undergoing development, but it has working prototypes that have seen road time in Maryland. With IBM Watson, it can listen and talk back to passengers, telling them about things like the weather and good restaurants. And those restaurants may someday have 3D printers themselves.

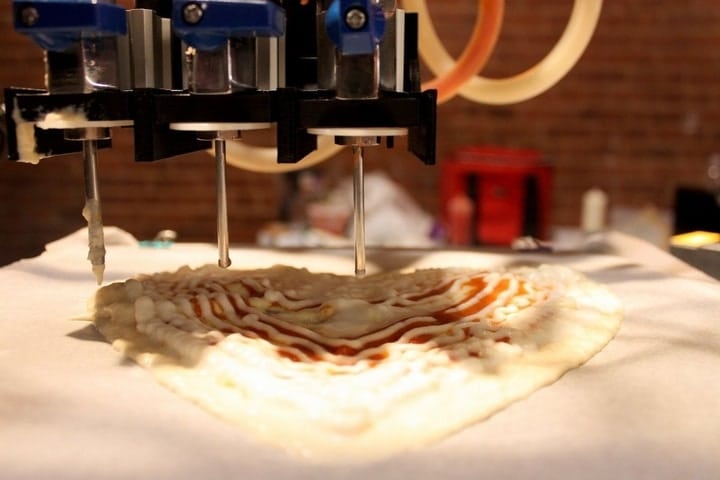

9. Printing a snack

Believe it or not, even food can be 3D printed. Printers generally don’t cook the food, so you still have to do some work, but they can take care of some tedious prep. All you have to do is load in the ingredients and then use a digitally designed file to print out your food.

Digital Trends

Before printing, the ingredients have to be puréed and then put in containers, which then go into the printer. So, some foods won’t be able to be 3D printed, just because you would never purée the ingredients. Like you probably don’t want a puréed salad. But there are some amazing foods already being printed.

10. Perfect pancakes

While people on the internet are trying to carefully make beautiful pancake art, the PancakeBot™ is doing it with ease. This 3D printer is made specifically for printing pancakes in whimsical shapes, like astronauts and triceratops. It prints directly onto a grill, to cook the tasty flapjacks. The varying cooking times change the color, making the design possible.

Gadget Flow

3D printing is perfect for difficult to prepare food, like pancake art. So it’s been used for intricate pastas and chocolate shapes. It’s even been used for small pizzas and burger patties. A pop-up 3D printing restaurant, Food Ink, is planning a world tour with its 3D printed food, furniture, and utensils.

11. Astronaut munchies

While 3D printing food on Earth may be just a novelty, 3D printing food in space is probably more useful. Space food is a fun thing to buy on Earth, but it’s hard to imagine eating only freeze dried stuff for months or even years. But astronauts have to. So anything that could improve upon this for long, deep space missions is very welcome.

Futurism

Also, the shelf life of the current space menu isn’t long enough for a mission to Mars. One company got a grant from NASA to make 3D printers that print pizza in any shape and can use a variety of doughs and sauces, making the pizzas completely customizable. But food isn’t the only way 3D printing will be used in space.

12. Up, up, and away

Last year, a rocket was launched from New Zealand with an engine created almost entirely from 3D printing. Since 3D printing can make parts more lightweight and more complex than traditional methods, it’s a nice-looking option for making things sent to space. Physics heavily restrains the total weight that can be shot to space.

The Economist

The Orion spacecraft, which NASA plans to take astronauts to the moon and then Mars, will have many 3D printed parts. They’ve said it’ll be over a hundred. However, 3D printed things aren’t just being sent to space, they’re also being made in space. All around, 3D printing is just very useful in space.

13. Spare tools

Astronauts are very isolated when on space missions and a lot of things can go wrong that they have to be prepared for. Say an astronaut is out in space, working on the outside of the spacecraft and she drops her wrench and it floats far out of reach. What then?

ESA

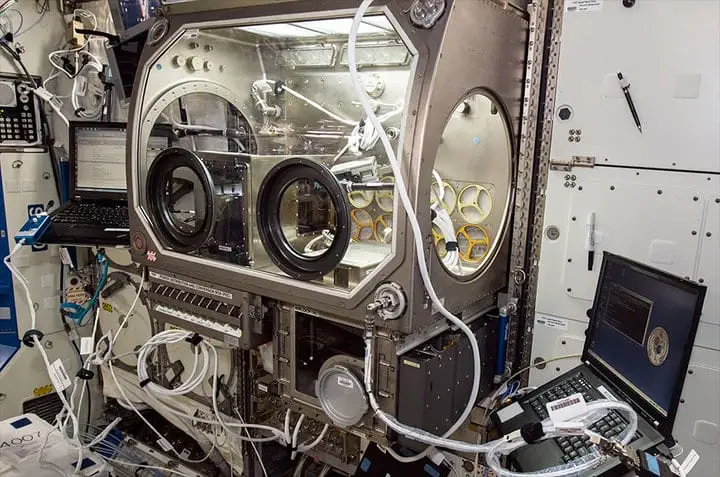

Well, NASA probably packed another couple of wrenches, because they try to be very prepared for anything. But soon enough, they won’t have to. There are now two 3D printers on the International Space Station. In 2014 they did one small print for man, and one giant print for mankind.

14. Wrench in the plan

Getting supplies to space can take months or even years, and for exploration missions it’s often impossible to restock from Earth. But in one week, someone designed a wrench that could be 3D printed, the file was sent to space, and the astronauts printed the tool in about four hours.

NASA

The ratchet wrench was made completely of layers of plastic, but it didn’t stay in space for long because they sent it back to Earth for testing. While this wrench was not life-saving, it’s easy to imagine 3D printing being used in a situation that would be life or death.

15. Made in Space

One company, Made In Space, is really going head first into space 3D printing. They supplied the International Space Station’s two 3D printers, but they haven’t stopped there. With NASA funding, they’re currently developing Vulcan, a device which would 3D print using metal. Metal 3D printing has been done on Earth, but not yet in space.

NASA

They’re also working on something called Archinaut that would have both a robot arm and 3D printer. Archinaut would be able to construct much larger things like space telescopes and repair satellites. Archinaut’s 3D printer recently set the Guinness World Record for longest 3D printed piece at over 123 feet long.

16. Creative materials

While 3D printing can be used to make extra copies of tools or small parts that weren’t onboard originally, the materials for them still need to be sent up to space. However, Made In Space hopes to eventually use sugarcane instead of plastic, so astronauts can just grow the materials for their printer.

collectSPACE

An even wilder idea comes from a yeast on Earth, which can eat the nutrients found in urine. Researchers are studying how to use the yeast to recycle astronaut pee into polyester, which could be used in 3D printers. The biggest problem is how to get the plastic out of the yeast once it’s made, because they’ve already genetically engineered the yeast to make polyester.

17. Astronaut healthcare

Along with making potentially life saving tools, 3D printing could be used for astronaut healthcare. Last year, a company called 3D4MD created the first 3D printed medical supplies to be used in space. Astronauts printed their design for a custom-fitted finger splint, which is helpful for all sorts of finger injuries.

3D4MD

Researchers on Earth already had hand scans of the astronauts, from when they made their gloves, so custom fitting the splint wasn’t too hard at all. And what’s being 3D printed in space, is also being 3D printed on Earth, but even better. 3D printing is looking to revolutionize the medical industry.

18. The new medicine

While 3D printing has not taken off for the average consumer, it has huge potential in the realm of medicine and health care. In fact, it’s already helping a lot of people. Plus, researchers have actually made 3D printers that can print living cells. That’s a huge change from the plastic figures.

Electronics360 – GlobalSpec

From organs and tissues to prosthetics to drugs, it seems like there are few things in medicine that 3D printers can’t help out with. Since no human is the same, the customization of 3D printing really allows for more personalized medicine. People have different needs and 3D printing can accommodate that.

19. Printed pills

Someday your medications might all be 3D printed. In 2015, the first 3D printed pill was approved by the US Food and Drug Administration for human consumption. The medication is called Spritam and it’s for people suffering from epilepsy. The drug was made by layering powder and binding it together.

Time

The 3D printing allowed Spritam to have a unique structure that makes it dissolve faster than normal pills, which is great for the people with seizures taking it. In the future, a lot more pills may be 3D printed along with tons of other medical parts. 3D printing is also giving people a hand in other medical endeavors.

20. 3D printed hands

Some people already have 3D printed body parts, since printing has proven very useful in making prosthetics. 3D printing allows for a more customized prosthesis, as it can create products with more intricate detailing than normal manufacturing. This is great for properly fitting prosthetics.

AOL.com

3D printing has been great for making prosthetics for children, because they tend to quickly outgrow normal prosthetics. But with the printer, they can just make the original design larger and then print it all over again, for much cheaper. Plus, they make them colorful and toy-like to make it more fun for the kids.

21. Scan and print

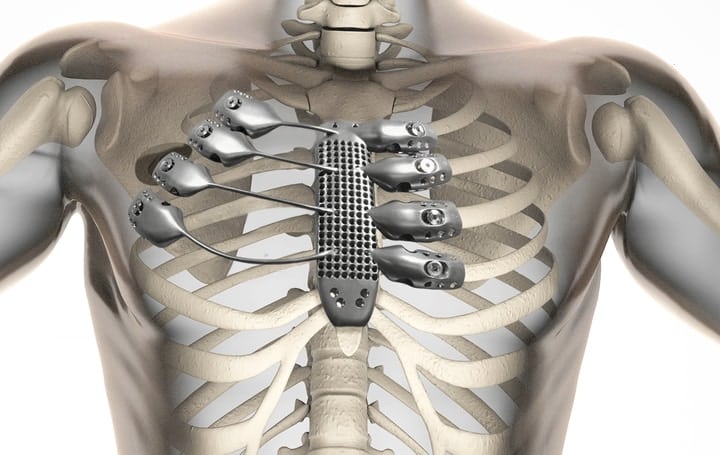

But while 3D printing can make customized pieces, it needs the help of another technology to do so. Combined with 3D scanning technology, 3D printing seems to be an unstoppable force for good in the medical world. 3D scanning allows doctors to get a personalized view of the area needing attention, making it possible to completely customize the print.

Engadget

A few years ago, doctors put a 3D printed titanium sternum and ribs prosthetic into a patient who had cancer in his chest. And while that is a permanent part of him, 3D printing has also been used to make parts that eventually biodegrade, like splints used on a baby’s trachea.

22. Prosthetist assistant

In developing countries, there are a lot of people who have lost a hand, arm, or leg. Hopefully these cases will decrease soon, but for now the people need treatment. Unfortunately there’s a shortage of people trained to make prosthetics, which is a labor intensive process requiring making molds and fitting the prosthetic.

3DPrint.com

3D printing can speed up their work and allow them to take on more patients, leading to more people having needed medical care. And there are probably a lot of other ways 3D printing can improve healthcare in developing countries. Some of the most promising applications are still being researched.

23. Bioprinting

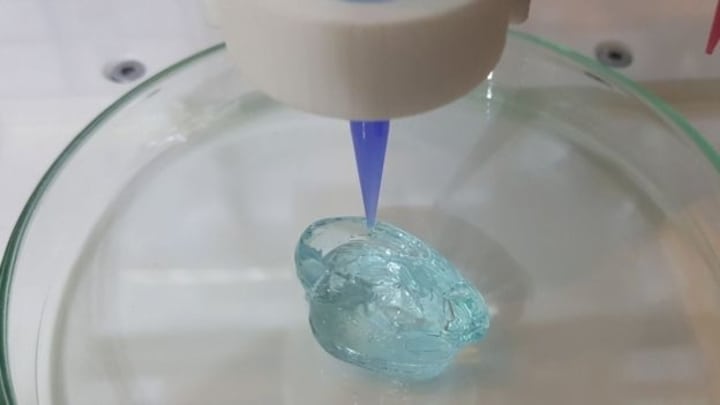

Not only can 3D printers be used for prosthetics, which are substitute body parts made of anything but actual tissue, they can also be used to make organic tissues. Some are used for research, like for example testing how a drug affects a human liver, but others will hopefully be used for transplants.

Cellink

The “bioprinters” work by using either specialized cells, like skin cells, or adult stem cells, which can become any kind of specialized cell. Generally, they also use something to hold the cells together. This might be a gel that eventually dissolves, or perhaps a scaffold made of collagen. But the cells aren’t just being printed into random shapes, they’re mimicking real body parts.

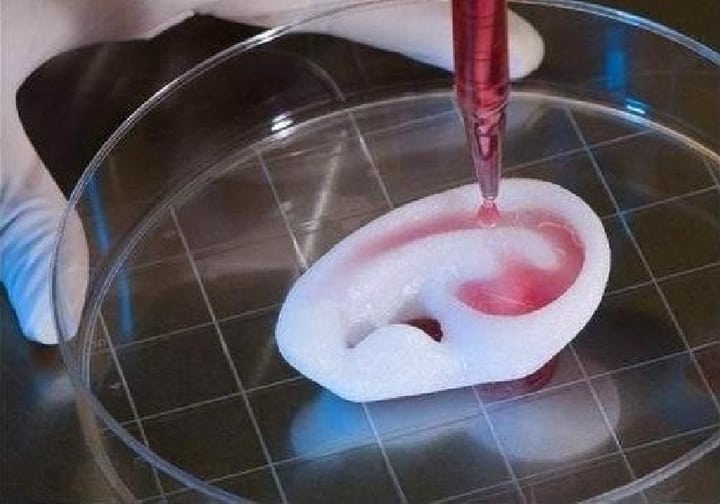

24. Thick skin

Last year, a group of researchers showed that it’s possible to print human skin. The skin could be used for transplants, when patients have irreversible skin damage, by printing new skin from the patient’s own cells. People will probably prefer having their own cells used, as opposed to someone else’s.

3Ders

The skin could also be used for lab testing. Lots of chemical products, like cosmetics and pharmaceuticals, have to be tested on something. It’d be better to test them on 3D printed skin than the skin of some poor rabbit. The 3D printed skin still has to be approved for use, though.

25. 3D printer, organ donor

Skin isn’t the only thing researchers have been working on, though, because they have really aimed high. Many scientists are trying to perfect “tissue engineering” by 3D printing cells, and they’re actually already printing tissues, bones, and muscles. Of course, tissues make up organs so that is the only logical next step for researchers.

BioVoice

Like the skin, a lot of these are on their way to being used for safe drug testing, but the aim is to make transplantable organs. The focus right now is on kidneys and livers, which have been printed in miniature size, but once those are made successfully other organs can follow. Small amounts of 3D printed tissues have been transplanted into mice already.

26. Holographic printing

Of course, there’s a reason we haven’t printed a transplantable organ yet. One of the biggest barriers to 3D printing functioning organs is printing them with functioning capillaries, which are tiny but necessary blood vessels throughout your body. The capillaries are where oxygen can get from your blood to your organs.

TED.com

However, one company thinks that they’re on their way to solving this problem, with holographic printing technology. This technology uses light to start a chemical reaction in the bioink. They say they’ll have the ability to get a fully printed organ into an animal in two and a half years.

27. Animal prosthetics

Not only can 3D printing be used for human healthcare, but it can be used for animals too. A loggerhead sea turtle was hit by a boat and lost part of his jaw because of it. A team from a 3D printing company scanned his face and, with veterinarians, they modeled a new jaw for the turtle.

YouTube

The researchers printed the jaw in titanium and attached it to the turtle’s face. And, a few years ago, a toucan lost half of its beak, but with 3D printing people were able to make it a prosthetic beak. While some people hurt these animals, others have enabled them to keep living.

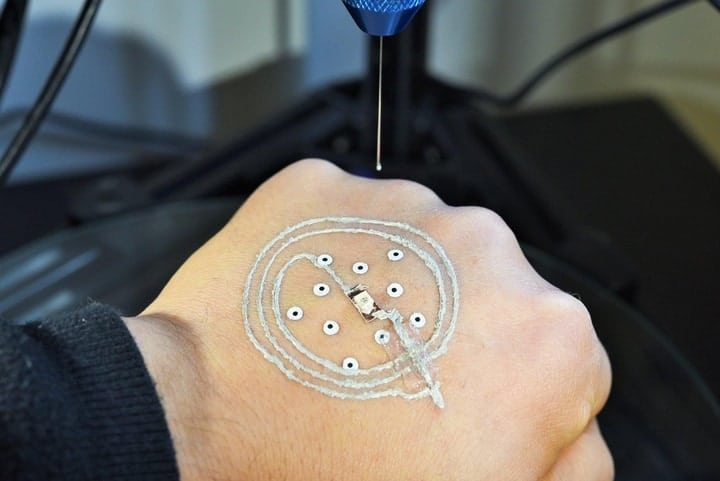

28. Electronic human

Nowadays, everything is electronic, so naturally 3D printers are in on that too. Using a conducting material for an ink, 3D printers can even print electronics. And while printing on uneven surfaces has been difficult in the past, a group of researchers has recently overcome this and for the first time printed electronics on a human hand.

Replicator World

They printed a small electronic LED light and circuit on the hand, which could be turned on wirelessly with a copper coil. In the future, this sort of technology could be used for printing sensors onto prosthetics or even electronics onto human skin. Imagine being able to print a cellphone onto your arm!

29. Plastic weapons

On the opposite side of healthcare is the recent use of 3D printing for guns. At this point it really seems that almost anything can be 3D printed. However, whether or not these guns work is based on the material they’re printed with. To print a working gun, the printer has to use really tough plastic that would withstand being fired, which isn’t what most people have at home.

Phys.org

People’s home 3D printers are limited by the materials they can print with and most won’t be able to use a strong enough plastic. One that could print a consistently working gun would probably cost $10,000 or more. With this money, people could buy like ten or more guns from the store.

30. Manufacturing the future

While 3D printing has often been seen as just for making trivial things like plastic toys, it actually has huge potential in a variety of industries from housing to space travel to medicine. 3D printing’s biggest advantage is its ability to make something completely customized, as opposed to mass manufactured.

deTeched

3D printing can make things with much more detail and intricacy than human hands or other technologies can. On top of that, it’s often cheaper than traditional manufacturing methods and less wasteful. 3D printing will probably feature prominently in the not-so-far future in industries like medicine, space travel, and housing.